Coding and Inspection

Overview

We are container handling experts with extensive experience working with print and vision applications.

Applications

Code directly onto bottles and cartons

Inkjet coding

Continuous inkjet (CIJ)

Thermal inkjet (TIJ)

Standard and UV inks

Laser coding

CO2 and UV laser

Laser ablation or using DataLase technology

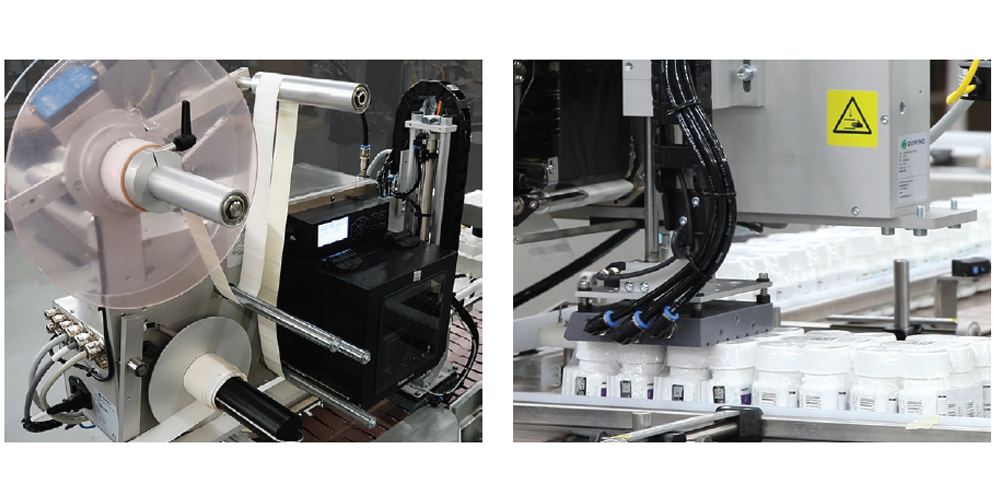

Thermal transfer coding / labeling

Print-and-apply labeling (bottles, cartons, bundles, cases)

Manual and auto application

Various hardware configurations

Inline coding along a stretch of conveyor

Coding at a dedicated station

Bottle coding within an Omega Unscrambler

2D data matrix and human readable codes

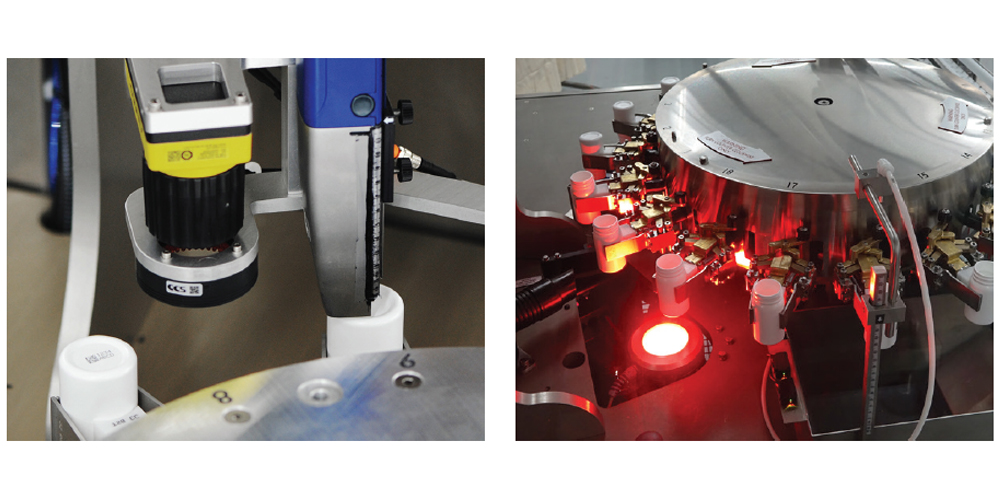

Vision inspection and reject handling

Serialized data management

Take A CLoser Look

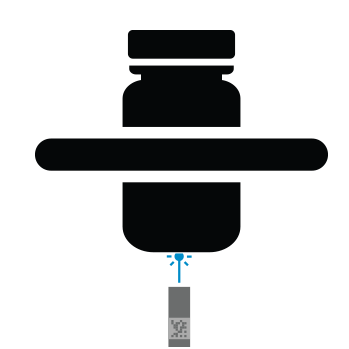

Bottle Coding (Inline)

Omega can bottom code bottles using side belts to space and convey bottles across a conveyor gap. A mounted printer aimed through the gap prints the code directly onto the bottle as it passes.

Alternatively, inline top coding onto bottle caps is possible with an overhead printer.

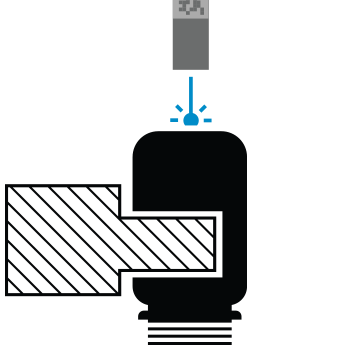

Bottle COding (Unscrambler)

Inside an Unscrambler, rotary pockets gently grip each bottle to maintain 100% positive control. The pockets can invert bottles, as needed, for presentation to the printer mounted above or below. Omega can integrate a CIJ or laser printer inside the unscrambler frame, as well as inspect and handle rejects.

Carton Coding

Omega offers the Intelli-Code, a high speed, inline carton coding and inspection system that can be equipped with a TIJ printer, CO2 laser, or both. Codes can be printed on the side of a carton.

Unit and Bundle Labeling

Omega builds labeling and inspecting solutions for individual units and packs. Omega has worked with many third party vendors to print, read, and associate data from unit codes with a parent label. .

Omega’s LabelSync offers printing, inspection, and code association for bottles. Omega’s PackSync offers print-and-apply labeling and code association for bundles (bottles or cartons).

Omega’s Vantage IL Unscrambler can even label bottles in the Unscrambler.

Case Labeling

Omega’s Intelli-Pac line of serialization equipment can integrate labeling solutions that apply a single-side or corner wrap label to a case. Applications have varied from semi-auto print-and-apply labeling to desktop printers for manual application and inspection.

Omega also offers the Intelli-Print, a serialized Case Labeling System.