Bottle Coding

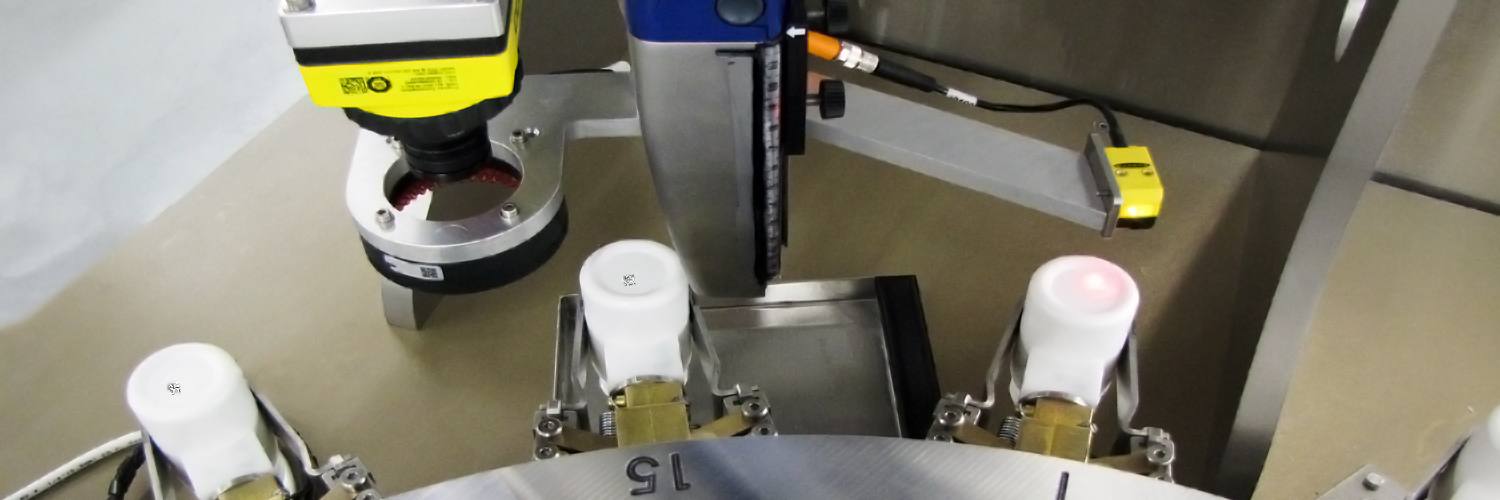

Omega has more than a decade of experience coding onto bottles at high speeds. Inside a Rotary Pocket Bottle Unscrambler, the individual pockets gently grip a bottle to maintain 100% full, positive control. The pockets can invert the bottles, as needed, to be presented to a printer mounted overhead or below the machine deck. Vision and reject stations can also be integrated inside the Unscrambler’s frame.

Capabilities

Print 2D and/or human readable codes directly onto bottles

Continuous Inkjet (CIJ), laser, and UV coding

Standard or UV inks

Laser coding with CO2 or UV laser; laser ablation or via DataLase technology

Coding within a rotary pocket style bottle unscrambler

Inline coding along a conveyor

Vision inspection and reject handling

Serialized data management