Intelligent Way to Case Pack units and Packs

Intelli-Pac is the premier end-of-line case packing and aggregation solution. Intelli-Pac involves a manual packing operation with the flexibility to incorporate semi-automatic technologies to form, label, inspect, and/or seal a case.

For a smarter, faster case packing process, Omega offers the Cobot Pack Assist for the Intelli-Pac. This collaborative robot works alongside an Operator to load bottles or cartons into a case.

Highlights

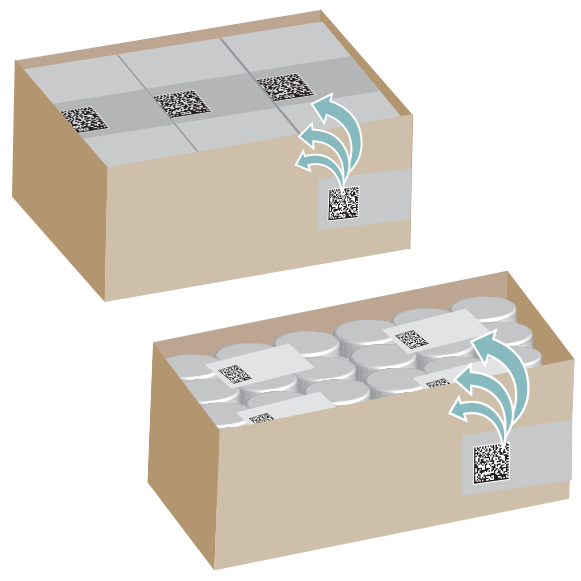

'Pack first, then inspect' operation designed for high integrity aggregation

Case pack and aggregate bottle or cartons, loose or bundled

Overhead layer inspection

Ready to integrate with a serialization data management software provider

Semi-auto options to case form, label and seal

Compact, mobile design

Anodized aluminum and stainless steel construction

Downloads

Intelli-Pac - Case Aggregation

Manual Intelli-Pac

Manual Case Pack Operation

Standard Features

Pack table with adjustable case positioning guide

Printer shelf

Overhead layer inspection camera mount

Enclosure for touch screen interface

Options

Case label desktop printer

Auto case labeler

Case taper

Additional level of aggregation (unit-to-bundle) featuring Omega's PackSync technology

Semi-Auto Intelli-Pac

Manual Case Pack Operation with Semi-Auto Assist

Standard Features

Integrated semi-auto case former and case taper

Domino corner wrap case labeler with Zebra printer

Overhead layer inspection camera mount

Touch screen to interface with machine operation

Split voltage enclosure supports NFPA 70E

Options

Infeed conveyor with optional compression relief

Additional level of aggregation (unit-to-bundle) featuring Omega's PackSync technology

Related Video

Go Further

Customers also considered these machines